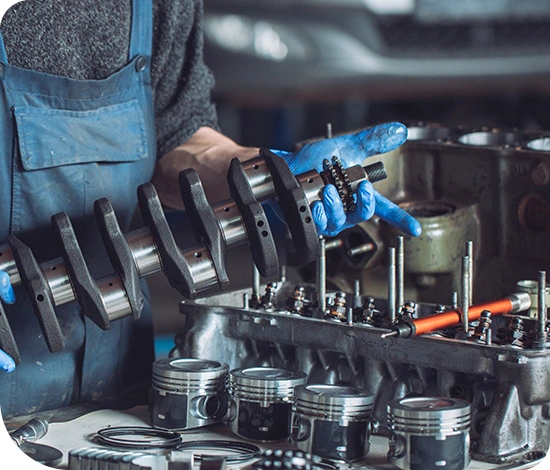

Automotive Parts & Accessories engineering industry is characterized with a wide range of products with multiple variants and time-to-market pressure. These manufacturers deal with an array of products, such as piston engine valves, control valves, propelling nozzles, and thousands of other components used to assemble automobiles. If designing an automobile or its components, engineering precision and accuracy is a must. This industry has high demands throughout the year, and hence pushes for higher production to cope up with these demands. Storing and warehousing these parts are also highly challenging.

Approximately 30,000 parts go into a single car. With new cars launched every other day, the demand for innovative tools and equipment has multiplied substantially. It is very tough for automotive component manufacturers to manage multiple vendors, sub-contracting, production, and dispatch of quality items.

ERP for Automotive Industry

Our ERP solution New Horizon is an ideal ERP for the automotive industry and can completely automate the industry so that various operations are completed as per the line-up. This assures elimination of delays and errors in the industry. This ERP software has the capability to create a chain of command and operations for the automobile industry that are executed smoothly through workflow. New Horizon ERP can control and monitor all the activities for this industry. Its cloud-server installation features allows storing all the information on central location servers, while enabling it to fetch the information whenever needed. The lean and agile architecture of New Horizon ensures to meet the production needs and handle every step in the fabrication process

Best ERP for Automotive Industry

New Horizon ERP is the best ERP software for the automotive industry that enables users to continue running the machines smoothly with accurate production schedules and keeping scrap and rejects low.

Key Benefits for Automotive Parts & Accessories Industry

- Ease in maintaining details of products, attributes, production process group, tools and consumables required for similar product

- Save production time with work Center/ Process wise production Planning

- Multi-level BOMs to meet the unique needs of manufacturing processes, reflect critical interdependencies, routings for accurate scheduling and planning

- Estimate production costing with per hour production capacity

- Process/ Stage wise status of Customer Order which are under production

- Load Analysis, Machine Efficiency. Definition of Cycle Time for processes and machines